Measure, evaluate, act

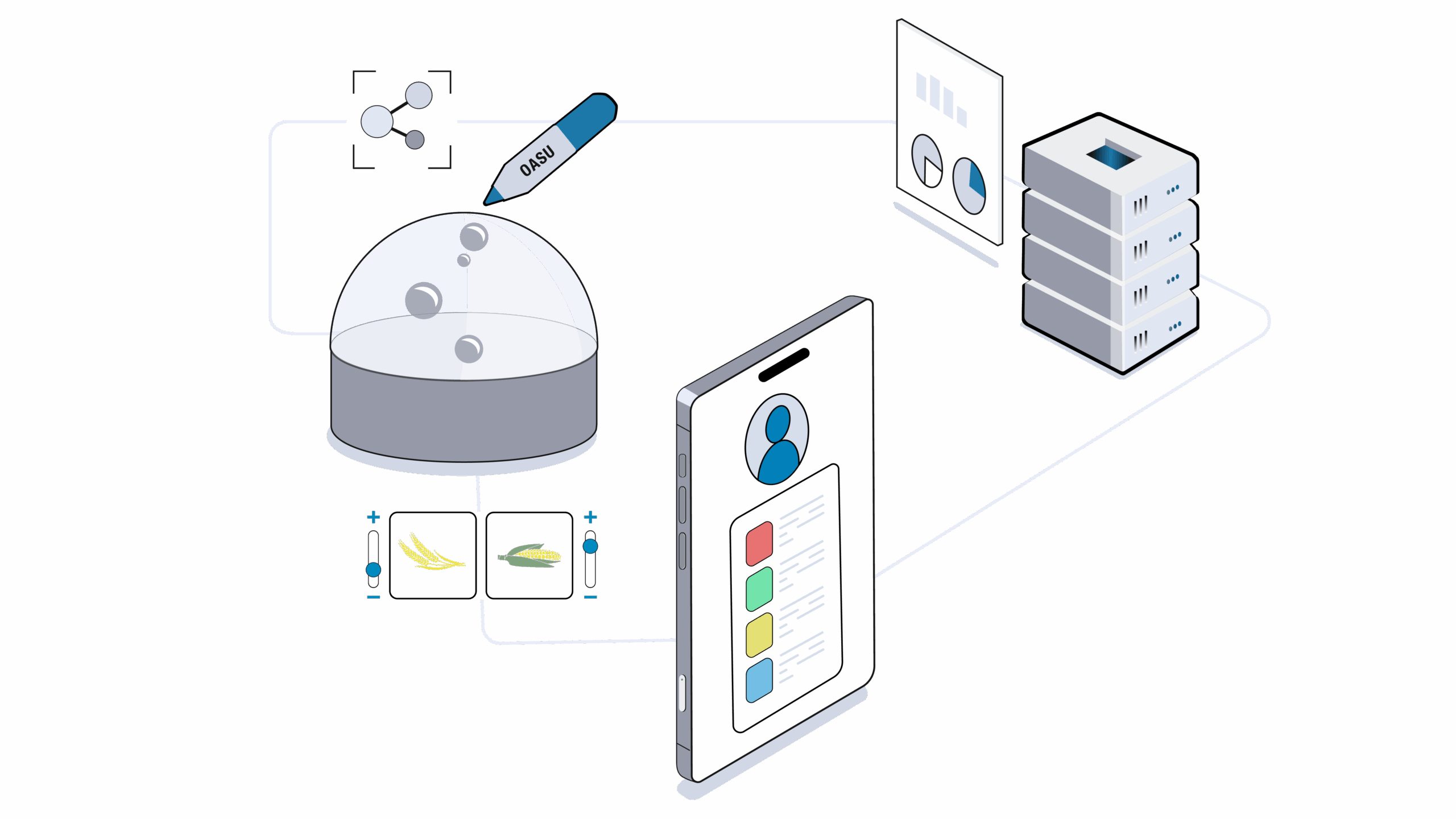

Short-chain organic acids are present in biogas not only in their liquid form in the substrate broth, but also in gaseous form. This is exactly what we use. We measure the proportion of these gaseous acids. As we avoid the time-consuming preparation of liquid samples, much closer and more frequent sampling is possible.

The acid contents determined are directly integrated into a dense, high-resolution data history of the fermenter. Precise dynamic evaluations can be derived from the visibility of this "breathing".

From this newly acquired quantity and quality of measurement data, it is only a step to well-founded action. Operator decisions are based on a more reliable data basis. Not only are critical individual cases avoided in good time, but the ongoing process can also be optimized continuously and statistically.

BIOGAS ANALYTICS

OASU SENSOR

THE HEART OF TECHNOLOGY

With our Organic Acid Sensing Unit (OASU), we are able to reproducibly measure the organic acids present in the fermentation gas.

PERMANENTLY

ON SITE

The OASU sensor takes its samples directly from the gas chamber of the fermenter, i.e. the device is permanently installed and operates permanently in your system.

AUTONOMOUS

AND SAFE

The OASU sensor independently and continuously sends measured values to the ATFO server. The analyses are subject to self-monitoring to ensure measurement quality.

OPERATIONAL MANAGEMENT

SYSTEM

SAFETY FIRST

The operator of your biogas plant is guided by our Operational Management Service in his safe course of action.

GET BETTER DIRECTLY

Our Operational Management Service provides you with data-supported recommendations for immediately realizable measures just five minutes after the measurement.

WIN ITERATIVELY

The measures implemented to optimize the fermenter can then be compared with the next measurement and its evaluation and adjusted if necessary.